I sistemi produttivi

SISTEMI PRODUTTIVI

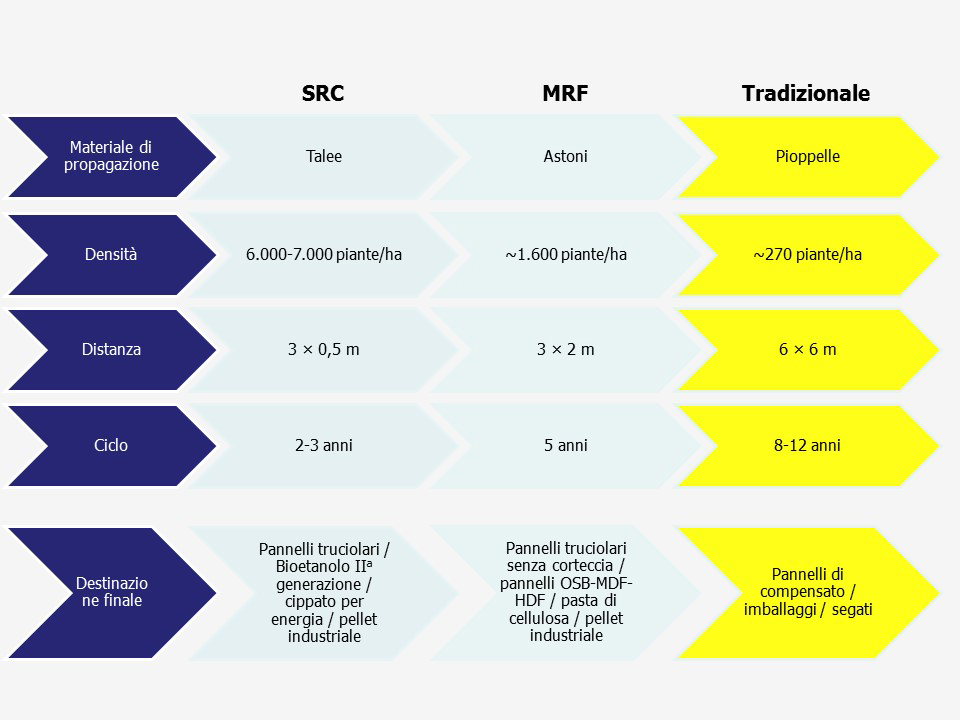

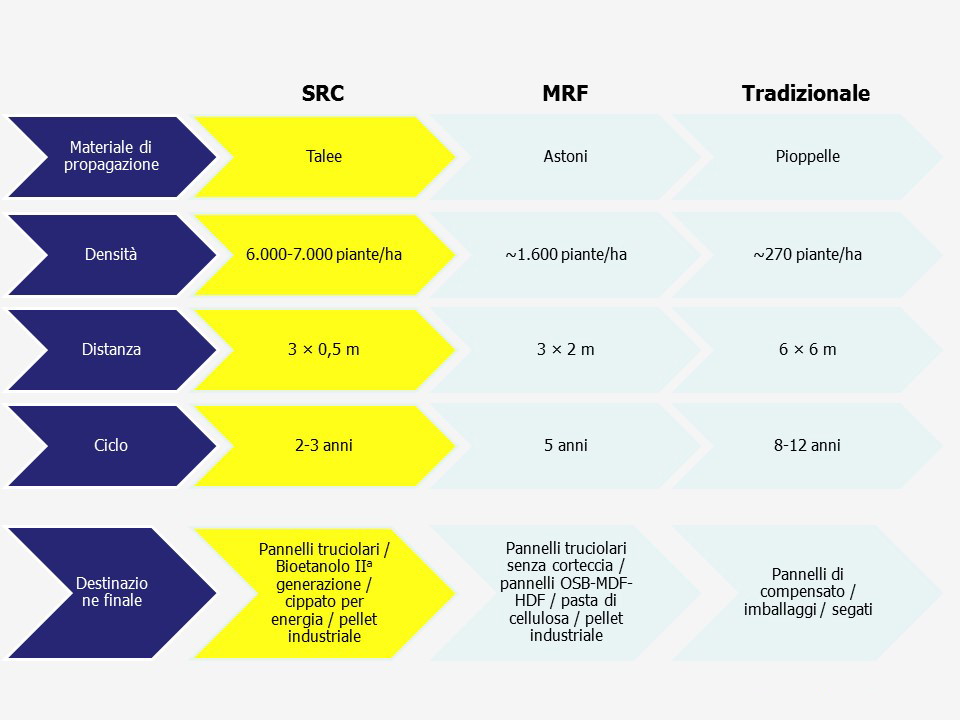

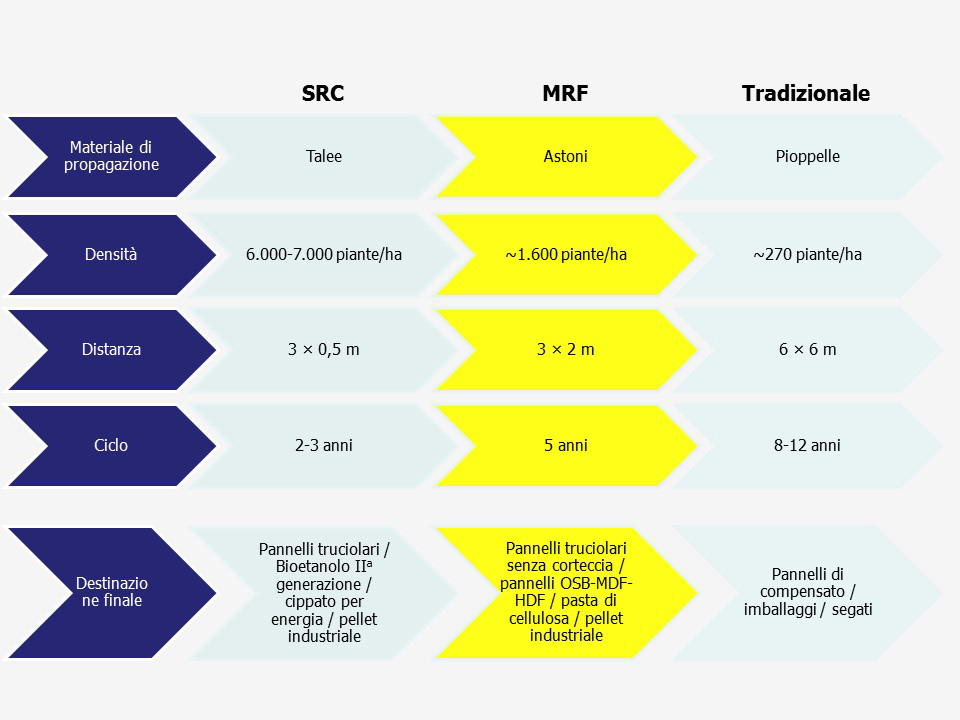

Il modello colturale SRF (Short Rotation Forestry) è la coltivazione per la produzione di biomassa, prevalentemente cippato per usi energetici o come materiale d’industria, di pioppi ibridi a rapido accrescimento che, piantate con un elevato grado di densità (6.000 – 7.000 piante per ettaro) e gestite con idonee tecniche colturali, vengono raccolte con cicli di taglio assai più frequenti. Le SRF prevedono turni di 2-3 anni con piante disposte in file singole.

Il modello colturale MRF (Medium Rotation Forestry) può essere considerato come intermedio tra quello tradizionale e SRF: i turni sono leggermente più lunghi rispetto a quelli previsti nel sistema SRF, (Ciclo di 4-6 anni), e le piante hanno una densità inferiore (~1600 piante per ettaro).

La pioppicoltura tradizionale si basa su impianti con una densità di 280-300 piante per ettaro e turni di 8-12 anni; prevede l’applicazione di tecniche colturali relativamente intensive e spesso di carattere agronomico (concimazioni, diserbi, potature, ecc.) per agevolare le potenzialità produttive delle piante impiegate.